Member's Planes and Projects

Chris Gill - Murphy Super Rebel - SR2500

This Murphy SR2500 plane was built by Chris and Larry Gill. It was one of the first Super Rebels built (s/n 025). Purchased in 1997, the build took four years. First flight was on July 31, 2001.

Factory support from Murphy Aircraft Company of Chilliwack B.C. during the build and over the past 9 years has been outstanding!

Put her on floats in May of 2003. Floats were built by Keith Kinden of Montana Floats in Libby Montana.

We have over 100 trouble free hours on the plane and could not think of a better plane for a family of four flying in Alaska.

Currently have the plane in the garage installing droop wing tips and possibly vortex generators. Chris Gill

Mar 16 2008

Chris Gill - Smith Super Cub (PA-18 Replica)

Here are a couple photos of our new project, a Smith Super Cub (PA-18 Replica).

We purchased the kit last week and our starting the build in our garage in Turnagain.

Chris Gill & Larry Gill

Chuck May - RV-7A

Started in 2001, Lycoming O-320, as of May 4 2006

Craig and Debrya Walls - Murphy Rebel

Craig and his wife also have a web site: http://www.alaskanrebel.com/

Dick Reeve - Lancair Legacy

Why a Lancair Legacy? It's longer, stronger, quicker, and slicker.

All composite carbon fiber pre-preg.

Dec 2002 took a tour of the factory. Ordered kit in April.

Did the 14 day builder's assist course at the factory. The help, instructions and use of the factory jigs was worth at least 6 months of working alone.

Fuselage and wing stubs are 10 feet wide. Lifted the fuselage on the 'rotisserie' and tilted it 45 degrees so that the whole assembly was only 8 feet wide.

Trailered the fuselage up the Al-Can from Oregon.

Started in August 2003 "they said it would take 800 hours to build". Figured it would be in the air in August 2004.

Summer of 2004 - mix epoxy, add micro-balloons, apply, sand off, mix epoxy, add cotton strands, apply, sand off. Spent the whole summer sanding.

There are 60 fittings in the hydraulic system.

Since August 2003 - It's 29 months now and 2,600 hours into the build.

| 230 | Systems - hydraulic, electric, controls |

| 600 | Bodywork |

| 164 | Engine build-up |

| 16 | ELT |

| 100 | Avionics |

| 800 | Structure (That's where the factory came up with 800 hours!) |

| 2,600 | Total Hours |

67 years old when started

Demonstration ride at the factory. Powerful, stable. In 3-4 minutes, you can climb to a 9,500 foot cruising altitude. 210 knots cruise speed

You don't move the stick around with your arm, all you have to do is just wiggle the stick a little bit.

Delightful - 240 knots cruise @ 16 gal/hour 230 knots @ 13 / hour

66 gallons fuel 1500 lbs empty

During certification tests statically loaded to 14 Gs. Wings did OK, it was the fuselage at the main spar that wrinkled, so they added some doublers at that point.

Engine weighs 500 lbs 370 HP Continental ??540 "hot-rodded" 1 magneto, 1 electronic "blue laser??" It really runs off of the electronic ignition. It advances the spark, more power, better economy. If he really wanted to, he could turn the magneto off, but why do it?

No vacuum system. Dual alternators and battery, Blue Mountain EFIS

Elmer Webster - Zenith CH 701

This is what a GPS trail looks like when you're out in the practice area across the inlet for 32.2 hours and do 85 landings at Goose Bay.

Elmer says "While out at the Little Su last Sunday, I happened to catch a couple shots of the shy and wily CH 701 in its natural environment."

There is a skinny vertical line going down across the cowl to the ground. It's not a computer artifact, it's a fishing pole!

Almost ready to fly - as of Sept 3 2006

Keith Southard - RV-9

Interior is done! Engine compartment is done! All wires and hoses are clamped or otherwise tied into place.

Nose gear leg, wheel fairing, and lower intersection fairing are done except for painting.

Main gear leg and wheel fairings are done except for the intersection fairings and paint.

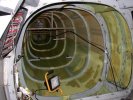

I am going to be applying the final layer of glass to the lower windshield molding tomorrow night and begin the process of molding the cover strip that goes over the gap between the canopy and windshield roll bar. (you can see some of the black tape used for masking in the photos) I probably have a week of work to finish the windshield and the moldings. Mostly just time waiting for the epoxy to cure.

I'm hoping that my prop and spinner arrive soon so that I can finish the installation of the cowling.

Ordered paint today and will soon start painting the tail and the canopy. Both must be removed for painting.

I'm scheduled to move back into the hangar in 3 weeks to begin final assembly and prepare for the FAA inspection.

Cheers! Keith - as of Sept 19 2005

As of Aug 2006 at Birchwood:

Mar 2008

Lars Gleitsmann - Dornier Do27-B3

Hi,

Here is my Dornier Do27-B3 Cold-War-Warbird, restoration was started in summer 2005, when finished it will most likely be the only 100% accurate restoration of a GAF (German Air Force/ Bundesluftwaffe) Do27 that is airworthy. It will have 100% original instrumentation, some old radios, and hidden modern stuff as necessary. Naturally it will have the original paintjob. I found it as a total derelict and it will now enjoy lots of new "old stock" parts (NOS).

Mar 2008

Lars Gleitsmann - Aermacchi-Lockheed AL60-B2

Aermacchi-Lockheed AL60-B2, which was only significantly cleaned up to this day. I bought it in fall 2006. Lockheeds like this one were used in Africa, by the British in Rhodesia for close air support as FAC's, also as liaison aircraft.

Both project airplanes were shipped from Germany to AK successfully in one 40 foot long HighCube Steel shipping conatiner, no damage to them occured, due to 7 welded steel structures, wooden cribbing, lots of foam, 3 months of full time work and the help of relatives and friends in Germany.

Best regards,

LarsRandy Tyler - Avid MK IV

I bought it in 1999 already completed as a tricycle gear with a 670 Rotax. I changed it to a tail dragger using Airdale wide gear and I also modified a set of ATV wheels and tires to work with the airplane, upgraded to Matco triple puck brakes and upgraded to a, 8" Maul tail wheel. At about 200 hours of flying the 670, had an engine failure. I changed it to a Rotax 582 and have over 200 hours on this motor. I'm currently working on a new stretched and widened fuselage that will use these wings and horizontal stabilizer from the Avid, but I am building a Subaru EA-81 motor for it. The Avid is a very fun and forgiving plane but has very little room; I'm hoping this conversion will give me the advantage of more room without too many compromises.

December 2010 Update....

My plane is an Airdale Avid Plus. It uses the Avid Heavy Hauler wing but the fusalage is 18" longer and 6" wider than the Avid Mk 4 (47" at the shoulder) with a larger balanced rudder. The flaperon mixer assembly is moved under the seat and uses push/pull cables to the flaperons, a push/pull tube to the elevator and standard cables to the rudder. The entire area behind the seats is open for baggage. The seats quickly pop out and it is 6' from the front seat frame to the back of the baggage so I can sleep in it. I did the slow build on it; interior, fabric, paint, instruments/wiring, built 1 motor but had trouble with the redrive so ended up getting a Stratus short block and redrive and swapped many of the custom parts is already had. I ended up doing major modifications to the cowling to install the dual custom radiators in the nose and used a 72" ground adjustable Warp Drive prop. I built the landing gear based on the Airdale wide gear but 5 1/2" taller and with three connection bolts to the fusalage and a wider frame. As mentioned, I also raised the skylight to give me a more comfortable head clearance with headset or helmet. So far I am very pleased with it; it is a very easy airplane to fly, very stable and still has the sporty feel of the Avid.

Here are some pictures of my baby; about 4 years in the building process. It has a 100 hp Subaru EA81 Stratus motor and redrive, MGL avionics flight and engine monitoring instruments, raised skylight, extended baggage, lengthened heavy duty gear, 28 gal fuel capacity and is in the light sport category. Cruise at 80 mph burns 2.8 gph of mogas on the fuel flow meter. I have really been enjoying flying it and have 10.5 hours on it now. I just got my skis rigged and on it last weekend but didn't get a chance to fly it. In these pics it has 21" tires on it but will put my 26" Alaska Bushwheels on it in the spring.

My favorite flying is exploring back country areas and my favorite place is up the Knik River / Lake George area. I enjoy talking to anyone about my project or theirs.

Randy TylerRick Davis - Producer

At the Valdez May Day Fly-In 2007

| Builder: | Richard L. Davis |

| Location: | Eagle River, AK - USA |

| Aircraft: | Richard L. Davis - Davis Special |

| Engine: | Lycoming - O360 A1D |

| Prop: | McCauley - 82-40 - Constant Pitch |

The Davis Special is an experimental 4 place super cub type project with a 180 hp Lycoming engine and a 66" chord Riblett Airfoil wing. The riblett airfoil has a chord that is 1.5" thicker and 3" longer than a Piper airfoil.

It was built under the supervision of Steve Bryant who holds the STC for the Producer Aircraft. The Producer is a certificated 4 place Super Cub created by modifyig a PA-22 or PA-20 in many ways, most notably by stretching the fuselage by 24 inches and installing PA-14 wings. Completion date: March 2007.

Website: http://www.mykitlog.com/Rick%20DavisRick Henry - Mustang II - N727RH

|

Plans were purchased and building started in September, 1983. 15 years / 3,500 man-hours later, it first flew June, 1998. An estimated 1,500 hours has been spent modifying it since the first flight. Current flight time is 990 hours, 1145 landings. It's now been to all 49 continental US states (no plans to ever take it to Hawaii..) including visits to San Diego, Key West, Nantucket, Quebec and the Bahamas four times. Has flown round trip between the Memphis, TN area and Anchorage five times. Was based in Alaska for some time, but now hangared at Olive Branch, MS.

It is flown IFR a lot, with an S-Tec 30 autopilot, Garmin GNS 430W, oxygen system and stereo intercom. |

|

It has just under 7 hours endurance at max cruise power, and is occasionally flown in the mid-teens, having cruised at Flight Level 200 (20,000') once on a four hour flight from Mississippi to Gettysburg, PA. Another flight from San Diego to Oklahoma City was made at 17,000' in five hours. Fuel capacity is 61 gallons, burning 8.6 at 75% cruise. All building, painting and avionics wiring was done myself. Some Lessons Learned (applicable to most Experimental builders), FAQs and more info is available on my web site for it at http://ExperimentalAirplane.com Rick Henry Rick@ExperimentalAirplane.com June 2006 - Chapter 79 Newsletter that has an article "Hohner's Corner" about my landing in the Mustang II's 49th state (Washington). |

|

Roy Glass - RV-6

After 8 years of on and off building, my RV-6 finally took to the air Saturday afternoon, October 22, 2005. Flight characteristics were excellent. Just like an RV should. Lycoming O-320 160 HP, Hartzell constant-speed prop, night VFR equipped, 1068 pounds with interior but no paint. More details later...

Thanks for all your help and moral support, especially Gale, who was always there to help buck the hard-to-reach rivets in the tail and fuselage and to help me decipher the plans.

Oct 24 2018

Shaun Milke - Quickie Q200

I bought my Quickie Q200 in Ohio in April of 2018. It hadn't flown in several years and there was no one to teach me how to fly it. I spent a week getting it flying, 2 hours figuring out how to fly it, then headed for Anchorage. It was a trip plauged by breakdowns and as soon as I got to Anchorage I decided to tear things apart and make them right...

My intentions for the airplane were to have a fast, efficient, and comfortable travel machine that could land where pusher canards can't and also double as a very modest racer in order to inexpensively (yeah right...) get into things at Reno. That is still the goal of the project, but previous damage and lack of proper maintenance have set me back at least a year.

I named the airplane "No Class", for a number of reasons, but mainly because it doesn't fit into any of the racing classes at Reno. I need to modify the airplane until it does a 200 mph qualifying lap, but the baseline numbers are quite a bit lower.

The airplane has a very stock O-200. Current top speed is 170 mph at 8 gph, but a comfortable and economical cruise is 155 mph at 5.4 gph.

Shaun Milke

Tim Coalwell - Zenith CH-801

Tim Rittal - Glastar

Apr 14 2008

My GlaStar has been patiently waiting to become a real airplane for almost 8 years now. Most of that time “The Plane” has taken a back seat to family, career, building a house and life in general. That is okay. Most of you can relate. The plan was always to build and pay as I could afford the time and money. I just didn’t realize how much time and money when I started. That’s okay too. I am getting there. I am now at a point in time when “The Project” moves to center stage. It is a priority. It has to be if I plan to fly this creation more hours than I spent building it. So I think 2007 will be the year my GlaStar takes to the air. Watch for it. I’ll keep you posted. Meanwhile, keep on building. Tim Ritall

GlaStar N55XP was started as a tail kit in 1998 and slowly built into a flying GlaStar. Total time to build was around 2500 hours. I received my Special Airworthiness Certificate on April 19, 2007 by our own John Davis, newly minted DAR. Yahoo!!.

The engine is an AeroSport Power O-360 (Lycoming clone), carbureted, 180 hp with a counter-weighted crank, Hartzell 80" constant speed prop and dual Light Speed electronic ignition. My panel consists of a Dynon 100 flight instrument unit, Dynon 120 engine instrument unit, a Garmin 296, Icom 200 comm radio, Garmin transponder and Sigtronics intercom. No gyros, no vacuum & no magnetos! I have two Odyssey batteries to run the electric. Currently I have 26" Goodyear (blimp) tires with plans for skis and floats later.

55XP cruises comfortably at 130 mph at approx 65% burning 8.5 gph. Top end somewhere around 140 mph. Stall speed with full flaps is 49 mph. Empty weight came in at 1,336 with a gross weight of 1,960 on wheels.

We'd like to put pictures of every airplane, if it's flying or not, built or not, for every member in the chapter. If you would like to have your plane or project shown here, email the Webmaster your pictures or web site links and info.

If you're more of a craftsman than a writer/photographer, you're in luck! We've got some of those.

Rob Stapleton (cell) 336-9425 rob.stapleton@alaskajournal.com

Rob is a reporter/photographer for the Alaska Journal of Commerce, and has graciously volunteered to visit everyone with a project, do an interview, take pictures, and write it up for our site.Chris Gill (cell) 227-9352 cgill@gci.com has volunteered to take pictures also.

Walter Yankauskas (cell) 351-3992 walteryak@gmail.com (Your friendly ex-webmaster) Wouldn't mind taking pictures too.

If you're looking for something to say, how about:

- Date of kit purchase

- Percent complete

- Hours spent building (to date or to completion)

- Engine type planned or purchased

- Other planes owned

- Other kits completed

- Hours logged in flight on current plane

- Words of wisdom or lessons learned (regarding building, test flying, flying, maintenance...)

- Contact information (if the builder wants to provide this)

- Favorite place to fly to

- etc....